Mikron Metalno specialize in the design and production of stamping tools as well as precision metalworking according to the customer's order. We offer cost-effective solutions for your needs for CNC milling and turning and other precision machining of metals, while maintaining quality and reliability. Continuous investment in the latest CNC equipment enables us to produce prototypes, individual parts and series, all manufactured to the highest standards, in stainless steel, aluminum and industrial plastic.

Laser engraving of all types of metals, fiber laser power 30W. We engrave on steel, stainless steel, aluminum. We engrave inscriptions, pictures, labels. Numbering of machine parts, plates, markings, etc.

Engraving

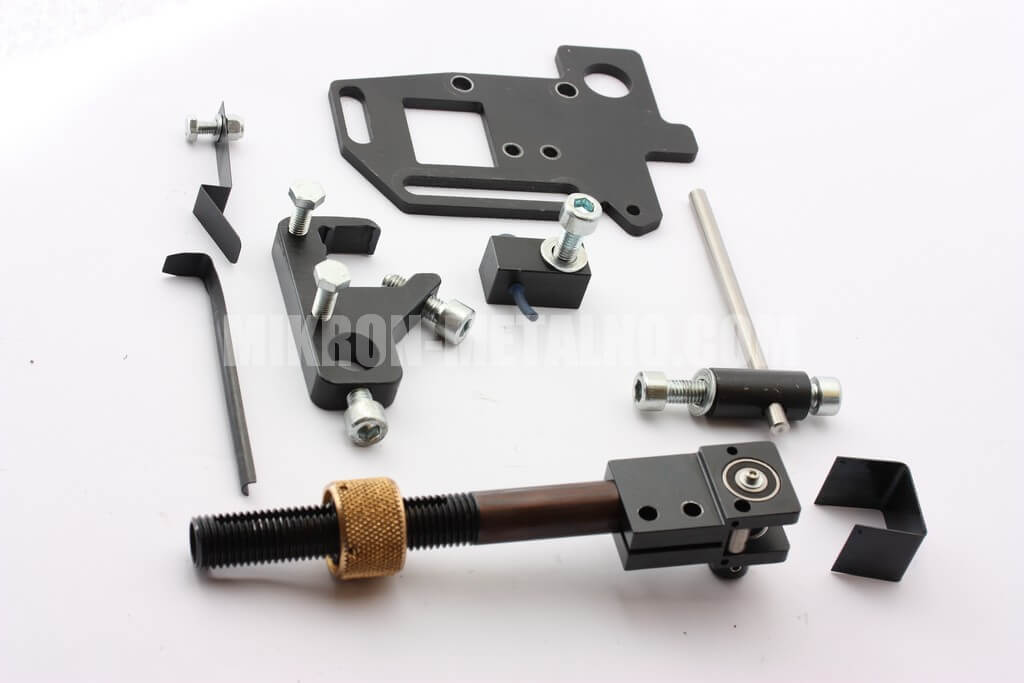

Stamping of metal parts. We own presses ranging from 10 to 100 tons. Production of stamping tools, production of stamped parts according to a sample, drawing or sketch. Production of various parts - blades, hinges, parts for carpentry, for the automotive industry, ...

Stamping, Assemblies

Production of various machine parts by precise machining on CNC lathes - milling machines for the needs of the aviation industry.

CNC Turning, CNC Milling

CNC machining on milling machines. Assembly of aluminum assemblies according to the model drawing. Production of various assemblies based on 3d models, drawings and samples. Assembling and completing all types of assemblies.

Design, CNC Milling, Assembly

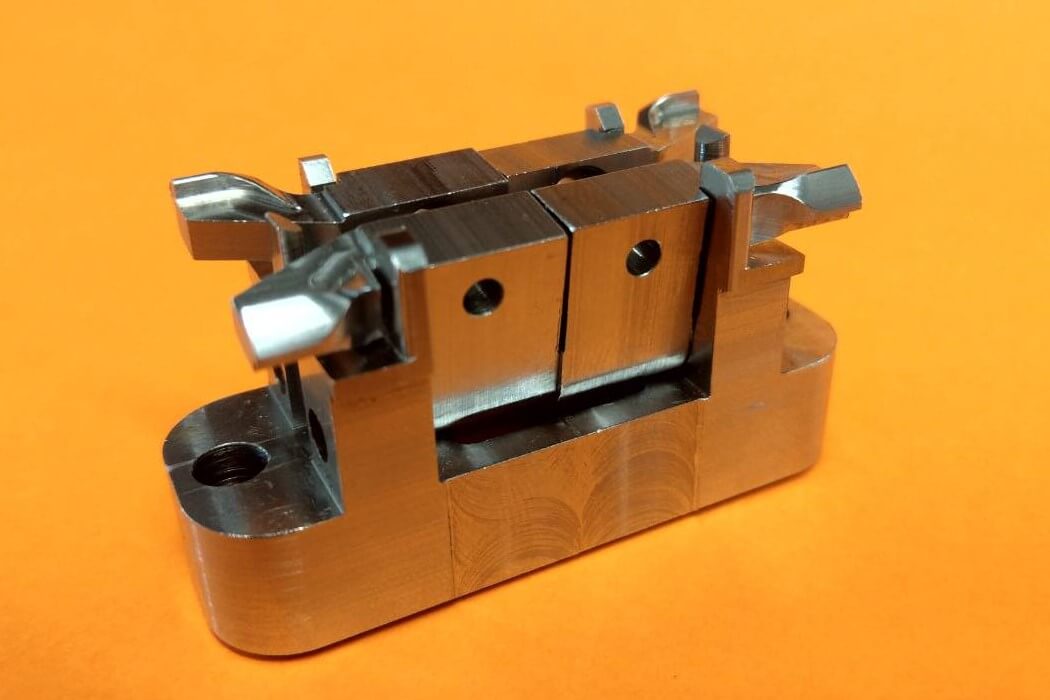

Production of parts and assemblies for machines in the field of cardboard industry, various types of processing. Finishing, assembling, painting.

Production of assemblies, templates, devices, assembly in the automotive industry.

Production of parts and assemblies with complex 3D surfaces.

In addition to the individual services listed below, Mikron-Metalno also offers you the most diverse production services: stamping tools: bending, cutting, injection mold for plastics, grinding of engine heads, processing of car disks, processing of truck drums, shafts, gears, sprockets, production of various machine parts according to your sample or drawing or sketch

Production and processing of parts on CNC milling machines of dimensions X-1500, Y-600, Z-600. Production or finishing of parts on tool universal and vertical NC milling machines dimensions of the work table 1000 x 500 mm.

Machining on a grinder for grinding flat surfaces of maximum dimensions - length 500 mm, width 300 mm and height 400 mm Machining on grinders for round grinding.

Production or finishing of the most various machine parts on universal and CNC lathes from all materials which can be processed by cutting Production or finishing of large and heavy parts on NC lathes of larger ranges with a diameter of up to 1200 mm.

Welding pieces and construction.

Stamping of metal parts. We own presses ranging from 10 to 100 tons. Production of stamping tools, production of stamped parts according to a sample, drawing or sketch.

Design of tools, parts, pieces as desired.

The company PMP "MIKRON-METALNO" d.o.o Lukavac, was formed in the first half of 2011, and originated from a workshop that was founded in 1998. It is a family own business. The company is 100% privately owned. The main activity of the company is metal machining, and it includes the following services: metal-milling, metal-turning, metal-grinding, as well as welding and stamping services. Machining is performed on CNC milling machines, CNC lathes, NC milling machines and grinding machines and presses. We own about 30 metalworking machines. The proximity of rail and road traffic gives the company an advantage in reducing transportation costs. It has its own production facility. The hall has a roundabout that allows unhindered loading and unloading. In our scope of work, we specialize in the design and manufacture of stamping tools according to customer requirements. We produce various parts of steel, stainless steel, bronze, hard plastics for international customers as well as the domestic market.

Our mission is to provide complete solutions in the field of metal machining, using our knowledge, planning, with the highest level of quality and precision, defined by the needs and satisfaction of our clients. Guided by excellence, vision and customer relations, we strive to follow the most modern and high-tech trends in the industry. Review and download our Quality Policy and our Environmental Policy

It consists of the following: We receive a model file from the customer. The most common formats include: STEP IGES PDF. Engineers develop the production process with optimization for: Efficiency and Quality. The machinist installs the appropriate working devices and cutting tools in our CNC machine. The piece is made - quality control examines the part. Sending products for additional processing, such as heat treatment, anodizing, dyeing, etc. Complete assembly or secondary processes. Quality control for final inspection. Delivery to the customer.

Something went wrong... Unable to load map... Please try to enable javascript

Mikron-Metalno d.o.o.

Tuzlanskog odreda b.b. 75300 Lukavac

Bosnia and Herzegovina

Tel/Fax: +387 35 57 47 07

Mob: +387 61 73 43 55

Mob: +387 62 33 60 89

Mob: +387 61 65 11 50

Mail: metalno@live.com